Formats and purity

Output forms

After refining, metals sourced from recovered materials are supplied in physical form with a purity of at least 99.95% in the format ordered and chosen by the client among the available range. Delivery of silver is carried out by the most trustworthy courier services which are fast and equipped to transport valuables, both in Italy and all around the world.

We purchase silver recovered from supplied materials, granting the best applicable purchase prices. We are able to handle all orders and build a long-lasting relationship in a reliable manner, given the high business volume that we have developed all around the world.

We have been working with metal accounts for years, i.e., tools that have been granted by international credit institutions from London, New York and Zurich, which guarantee the highest speed and trust when transferring virtual valuables from one side of the world to another, for gold, silver, platinum and palladium.

1,2 t - daily silver refining capacity

100 g/t – minimum quantity of precious metal required for the recovery process

We also recover very low quantities

We employ applied techniques and technology for silver recycling from all kinds of scraps, even low-grade materials. In our facilities in Castelluccio and Valenza, we are equipped to recover large volumes on a daily basis.

How we recover silver

We carry out pyrometallurgical processes in our facilities in Castelluccio (province of Arezzo) and Valenza (province of Alessandria). This technology is complex and constantly evolving: it is the result of large investments, such as the new foundry 4.0*, opened in 2021, as well as experience and research. We work alongside technology partners that lead us to potential innovations and improved production efficiency, with the objective of using as few resources as possible in our processes.

Preliminary preparation

Calcination, roasting and milling. We own 13 static furnaces where we process each batch individually.

Preparing the sample

Blending lasts at least 30 minutes and allows obtaining 30g samples that can represent batches weighing up to 3,000kg.

Data for each step

Analyses are carried out all along the process, as well as optimal, analytical protocols tailored to the quantity, thanks to state-of-the-art instrumentation.

The foundry 4.0

Rotary furnaces, TBRC and converting furnaces that allow obtaining a metal block free from impurities from smelting.

Controlled refining

Silver parting is similar to gold parting and consists of several immersions in solution. The recipe is detected automatically and is specific to each material.

Formats

Foils, grain, bars, ingots: a careful transformation process allows preserving the high purity of silver all the way through the process.

Eligible materials

Strict parameters, technology support and extended control system, starting from the shipping source.

Silver price in Euro and USD

| METAL | USD/oz | EUR/g |

|---|---|---|

| METAL: SILVER |

USD/oz: $ 91,1778 |

EUR/g: € 2,5049 |

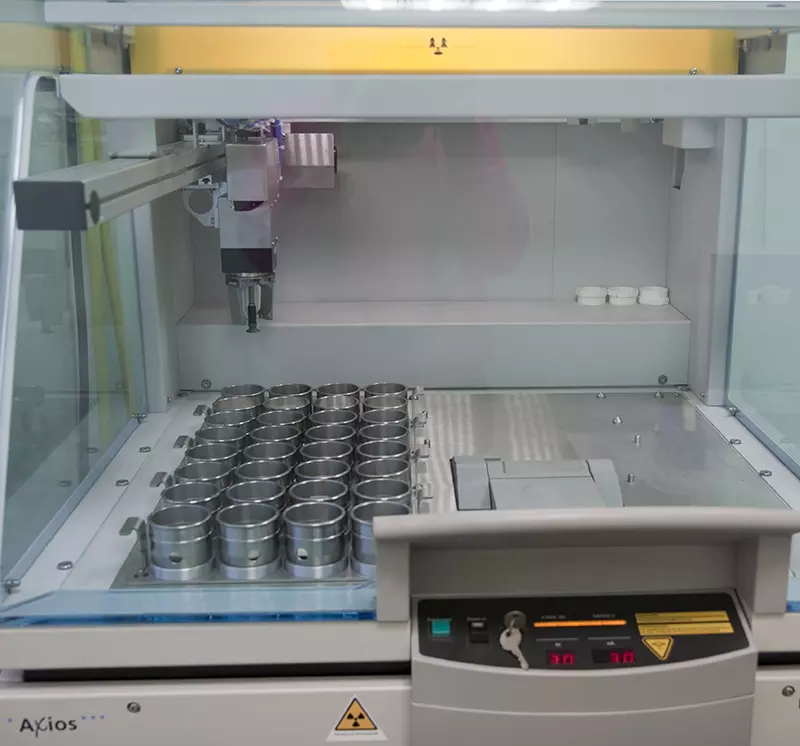

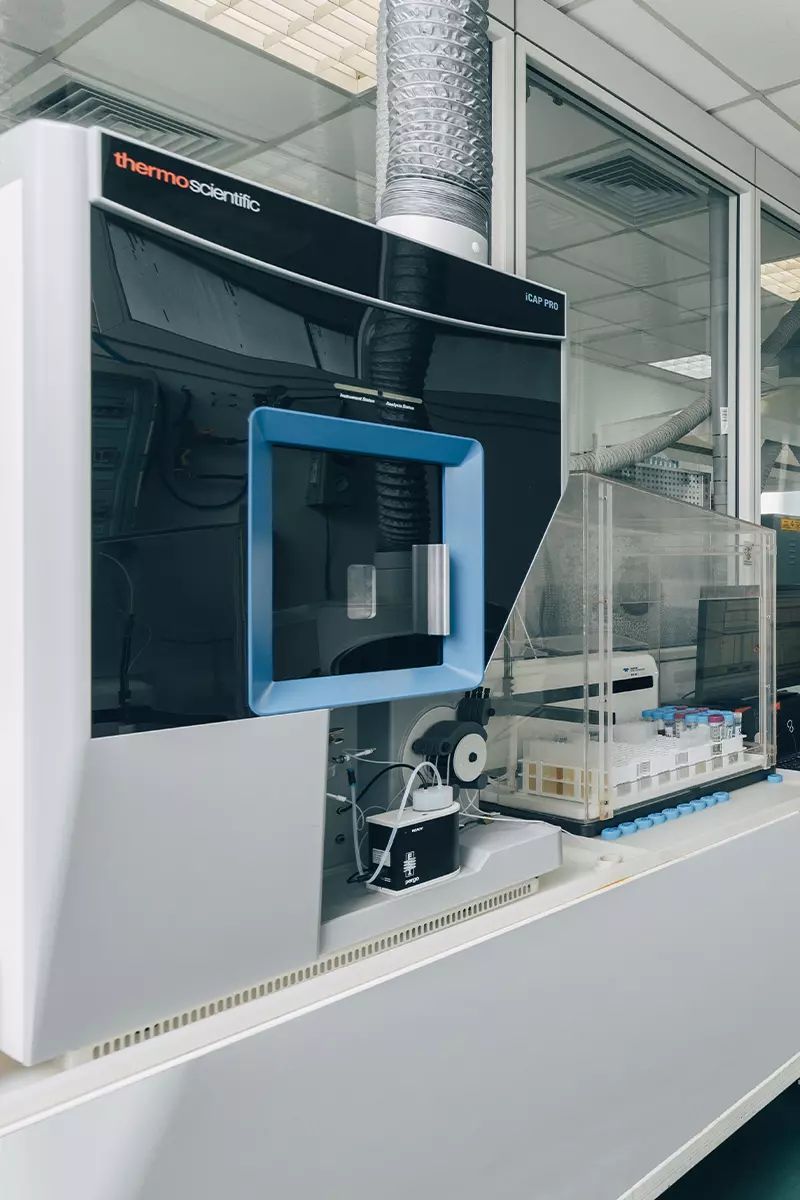

Silver analysis

High-pressure digesters, state-of-the-art ICP-OES, ED-XRF and WD-XRF

Analysis protocols tailored to the quantity

Applied analysis prior to the arrival of the material and during each processing step

WD XRF or ED XRF technology allow analyzing powders or compounds and determining the eligibility of the material. The best analysis protocols, including cupellation, an ancient and still efficient technique, or instrumental systems such as the ICP or potentiometric analysis, are determined on the basis of the mix of precious metals found in the material. We apply certified and accredited reference standards.

Book a consultation

Request a purchase or sale of silver or a refining service for materials containing up to 100g/t of metal.